Control your valves precisely and safely with our electric part-turn actuators.

Their versatility and compact design make them the perfect solution for your automation.

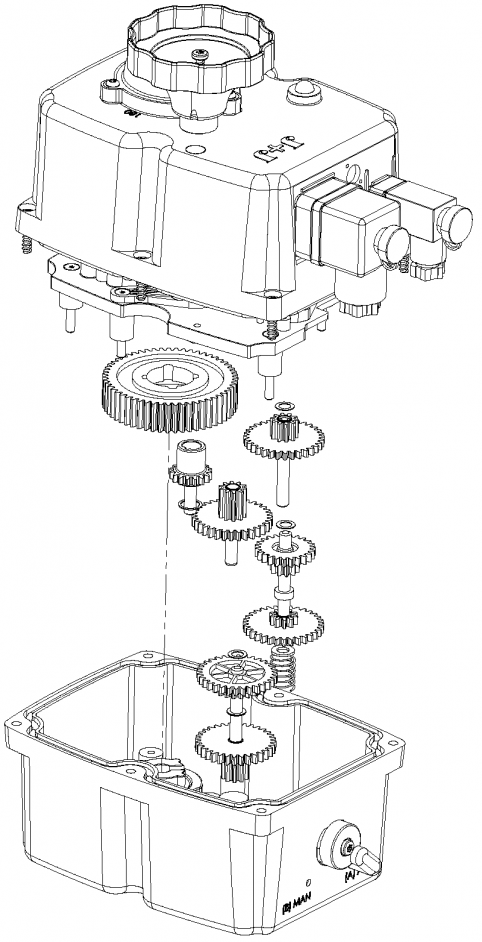

Our J4C part-turn actuators are the product of over 30 years of experience in the development of electric actuators. Our proven, maintenance-free gearbox forms the basis. Thanks to its self-locking design and switchable manual emergency override, you always have your valve under control.

The series includes model sizes with a working torque in the range from 20Nm to 300Nm

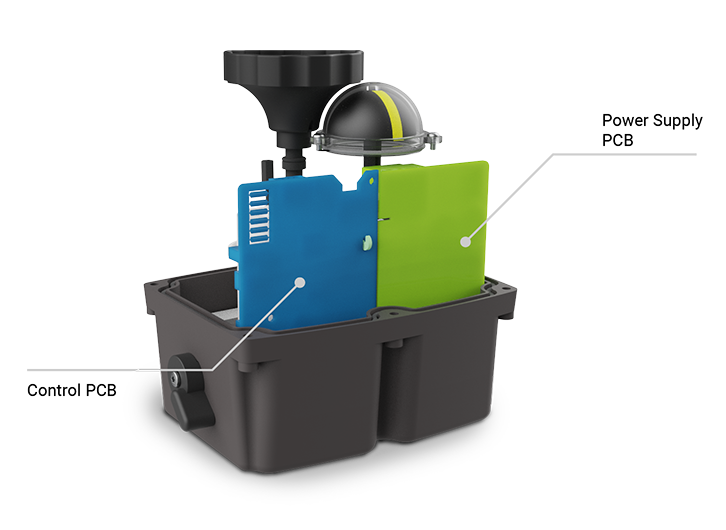

The gearbox is driven by a brushless DC motor and modern electronics. The innovative electronics house a microcontroller including our own software, which allows us to make many customisations and various connectivity options.

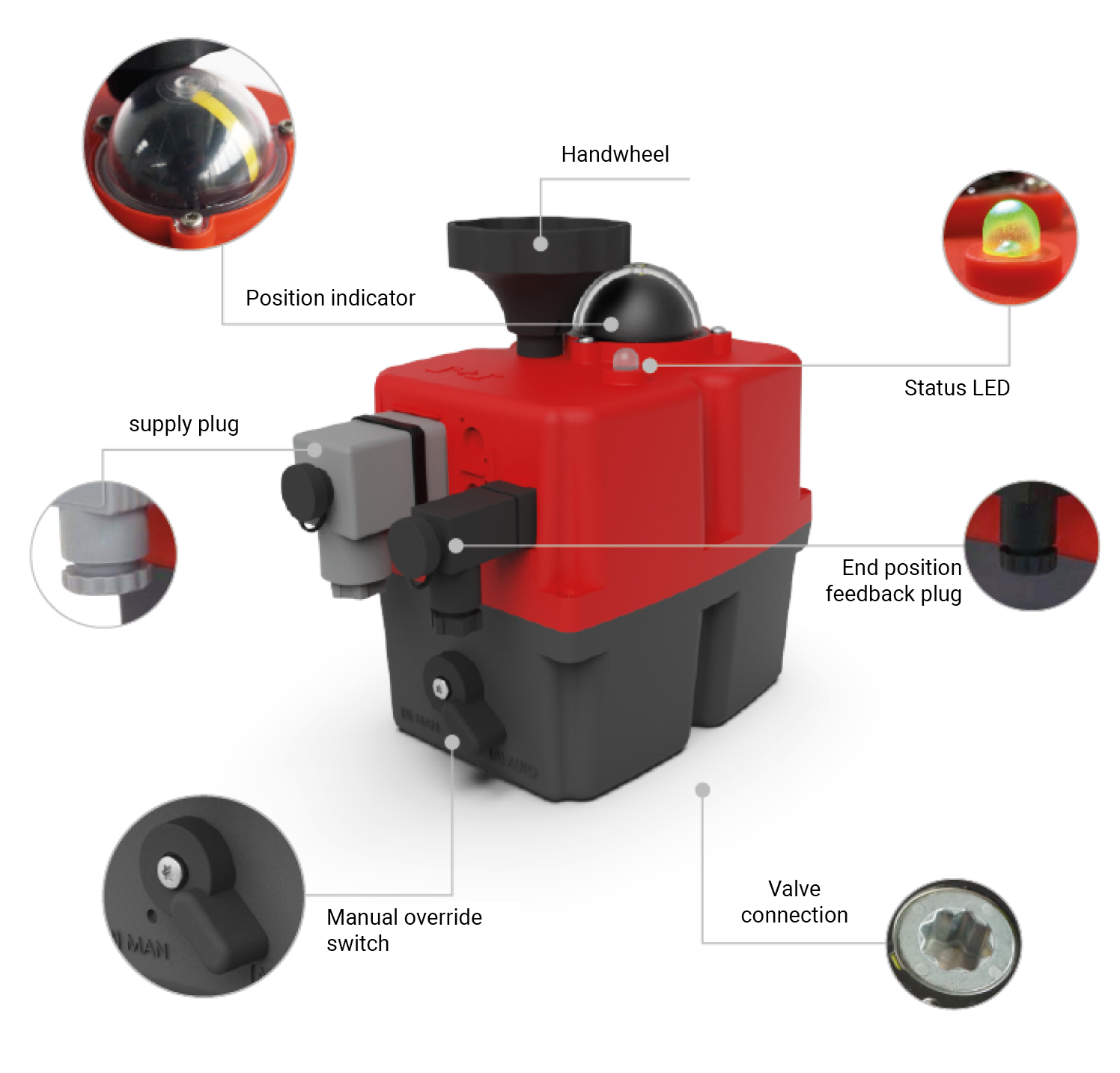

During operation, you have a full overview of the current position of the valve and the operating status of the actuator thanks to the position indicator and status LED.

Everything is securely packaged in our robust and corrosion-resistant plastic housing made of PA6 polyamide, which has an IP67 protection rating. The connection to the valve is of course standardised in accordance with ISO5211 / DIN3337. The electrical connection is made conveniently, without opening the housing, via DIN standard valve plugs.

What qualifies the J4C actuator as the best solution for your project?

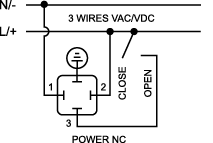

The internal power supply unit automatically recognises the connected operating voltage and converts it into the required motor voltage of 24V DC.

Operating voltages from 24V to 240V DC or AC (50/60Hz) can be connected in the ‘J4C-S’ voltage range.

Alternatively, the voltage range ‘B’ is available for applications with 12V DC or AC (50/60Hz).

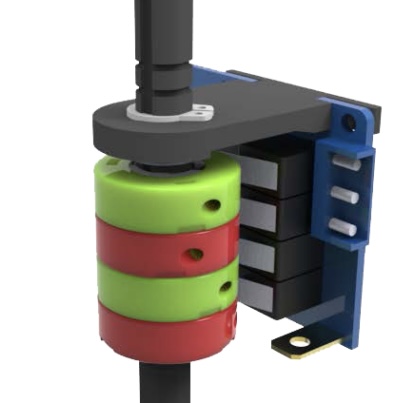

As this motor technology does not require carbon brushes to transfer energy to the rotor, the resulting friction and wear are eliminated.

This makes the brushless motor particularly energy-efficient and durable.

WARRANTY

By using our brushless motors, we can guarantee a service life of 60,000 switching operations or 3 years from the time of delivery.

What is the difference between a brushless motor and a normal DC motor?

In short: Brushless motors are better than brushed motors. Users can benefit from reduced maintenance, improved efficiency and reduced heat and noise. Brushless motors are synchronous machines with one or more permanent magnets. Power tools with brushless motors are now regarded as high-end products.

The status LED constantly indicates the current operating status with different colours and flashing cycles.

To prevent damage to the device or valve, the actuators are equipped with electronic torque monitoring, which stops the actuator if it is detected that the motor is consuming more current than permitted. The system interrupts the drive if the breakaway torque is exceeded and relieves the gears by moving them briefly by approx. 2° in the opposite direction. This makes it easier to switch the manual override and remove it from the valve. At the same time, the status LED indicates that the torque protection circuit has been triggered.

By moving the switch to the manual position, the motor is decoupled and the valve can be operated using the handwheel. After a short time, the motor stops and indicates the activation of the manual override via the status LED. The electrical function can be reactivated by switching to automatic and changing the controlled direction.

The actuator is equipped with 4 microswitches and a freely adjustable cam system. In addition to 2 microswitches for the motor stop, 2 further potential-free microswitches are available for the open and closed end position feedback.

A thermostat-controlled 3.5 W control room heater automatically keeps the interior temperature above 20 °C (68 °F) to prevent damage caused by condensation in the event of temperature fluctuations. Never switch off the supply voltage after the end of the movement so that the heating is permanently ready for operation.

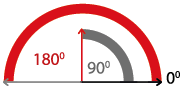

This value indicates the relationship between the operating time and the minimum pause required during use. The respective time for an operation must always be taken into account. The operating time refers only to the motor running time, so that the power supply may remain permanently active.

Example:

We assume a period of 10 minutes. 75% of this time the motor may operate the valve. This results in:

Maximum motor running time of 7.5 minutes

At least 2.5 minutes pause time

We provide comprehensive support for technical questions and problems relating to our products. We carry out inspections and repairs in our in-house service workshop. As every breakdown can cost money, time and nerves, rapid processing is essential for us.

To make replacement as uncomplicated as possible, we use a design with separate circuit boards. All circuit boards that come into contact with the installation and are connected to the plugs of our actuator can be replaced individually.

Model sizes

J4C 20

20Nm / 25Nm

J4C 35

35Nm / 38Nm

J4C 55

55Nm / 60Nm

J4C 85

85Nm / 90Nm

J4C 140

140Nm / 170Nm

J4C 300

300Nm / 350Nm

Parts overview

Optional equipment

|

DPS – Digital positioning systemThe DPS uses the integrated Hall sensor to precisely and contactlessly detect the current position of the actuator. This allows the actuator to be freely positioned in its operation angle as a positioner and permanently output its current position as an actual value. Possible Input and output signal: Function: |

Optional equipment

DPS – Digital positioning system

The DPS uses the integrated Hall sensor to precisely and contactlessly detect the current position of the actuator. This allows the actuator to be freely positioned in its operation angle as a positioner and permanently output its current position as an actual value.

Possible Input and output signal:

4-20mA / 0-10V / 1-10V / 0-20mA

Function:

NC / NO / Fail freeze

Open-close control with output signal

End position feedback

Two microswitches SPST NO (3A) with silver contact are fitted as standard.

Gold contact switches can be installed as an option for load-free monitoring of the end position feedback ( max.30V / <100mA).

In addition, a feedback signal based on transistors is available which, in addition to the open and closed end position, can signal an alarm contact or the centre position for 3 positions.

Related J+J products

J4M Multiturn

Our versatile J4M rotary multi-turn actuators are suitable for diaphragm valves, needle valves or globe valves that can be controlled or regulated via a rotary movement.